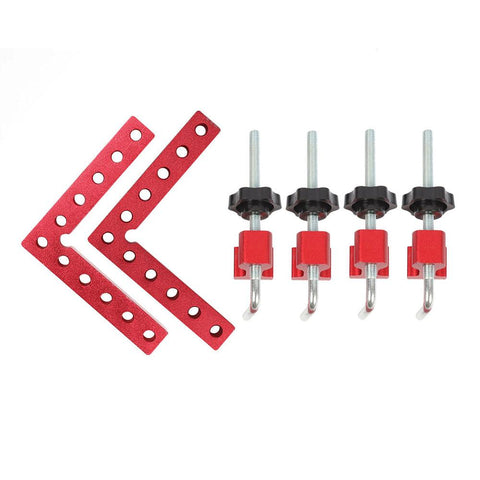

T-track Clamps

T-Track Clamps: The Secret to Flexibility and Precision in Your Workshop

In the world of woodworking, versatility and precision are key to ensuring high-quality craftsmanship. Whether you're building furniture, cabinetry, or engaging in other woodworking projects, the ability to clamp your workpiece securely and accurately can make all the difference. T-track clamps, often seen as a staple in professional workshops, offer a unique blend of flexibility, precision, and ease of use, making them an invaluable tool for any woodworker. These clamps are designed to fit into T-tracks on workbenches, jigs, or router tables, allowing you to adjust their positioning with ease while holding workpieces firmly in place during cutting, sanding, or assembly. If you're looking to elevate your woodworking projects, understanding the function and advantages of T-track clamps can significantly improve both the quality and efficiency of your work.

One of the most significant benefits of T-track clamps is their versatility. Traditional clamps often require you to find a flat surface or a specific angle to work with, which can be limiting in many woodworking tasks. In contrast, T-track clamps can be positioned anywhere along a T-track system, providing nearly unlimited flexibility when working on different-sized workpieces. The clamp's design allows it to slide along the track, so you can easily adjust the clamping position to suit your needs. Whether you're working with long boards, narrow strips, or odd-shaped pieces, T-track clamps give you the ability to secure your workpiece in the ideal position for the task at hand. This adaptability makes T-track clamps especially useful for complex projects that require frequent repositioning or adjustment.

T-track systems are typically incorporated into workbenches, fences, and jigs, which are often pre-drilled with T-shaped grooves that allow T-track clamps to slide along them. This integration allows you to build customized setups that maximize workspace efficiency. For example, you can quickly adjust the placement of the clamps when working with varying wood thicknesses or when making repetitive cuts. In a busy woodworking environment, this ability to reposition and reconfigure clamps saves time and eliminates the need for multiple clamping tools, streamlining your workflow and reducing clutter.

Another standout feature of T-track clamps is their ability to hold workpieces securely with minimal effort. Many T-track clamps are equipped with a simple but effective mechanism, such as a screw or lever system, to tighten the clamp once it's in position. Once engaged, the clamp applies even pressure across the entire surface of the workpiece, ensuring a tight grip without risk of slippage or misalignment. This even pressure distribution is crucial when working on precision tasks like sanding, routing, or assembling joints. Because the clamp holds the piece firmly without shifting, it reduces the chance of error, making it easier to achieve clean, accurate cuts and smooth finishes.

For woodworking projects that involve repetitive tasks, such as assembling multiple frames or working on identical components, T-track clamps offer a significant advantage. Once you've set up the clamp in the desired position, you can easily secure multiple pieces with the same settings, allowing for consistent results across all workpieces. This reduces setup time for each individual piece, enabling faster project completion without compromising on quality. The quick-release function on many T-track clamps also means you can rapidly adjust and remove the clamps, which is particularly helpful when moving between tasks or when you need to reposition your workpiece for a different angle or cut.

T-track clamps also offer enhanced safety by securely holding the workpiece in place, reducing the need for direct hand contact with the material while cutting, sanding, or routing. This added stability ensures that the workpiece stays exactly where you need it, preventing sudden shifts that could lead to mistakes or, worse, accidents. When working with power tools like routers or saws, having a stable and immovable workpiece is crucial not only for precision but also for safety, and T-track clamps provide that confidence.

Additionally, T-track clamps come in a variety of designs and sizes, allowing woodworkers to select the right clamp for the job. Some are designed to work with smaller jigs and projects, while others are heavy-duty enough to handle larger boards and panels. Adjustable clamping arms, padded surfaces, and rotating heads are just a few of the features available, depending on the model. These features allow the clamp to accommodate different shapes and sizes of workpieces, making them perfect for a wide range of applications.

T-track clamps are also an excellent investment because they offer long-term durability and precision. Made from high-quality materials like aluminum, steel, or durable plastics, T-track clamps are built to withstand the demands of frequent use in a woodworking shop. Their robust design means they won't lose their gripping power over time, and many feature replaceable parts to extend their lifespan. If you're building your woodworking tool collection, T-track clamps are a valuable addition that can handle a variety of projects and tasks without becoming obsolete.

In summary, T-track clamps are an essential tool for anyone looking to enhance both the precision and efficiency of their woodworking projects. The ability to reposition and adjust clamps along a T-track system offers unmatched flexibility, while the secure and even clamping pressure ensures stability during even the most detailed tasks. Whether you are working on large-scale furniture projects or intricate custom pieces, T-track clamps can streamline your workflow and improve the quality of your results. By investing in this versatile tool, you can ensure that your workpieces remain firmly in place, allowing you to focus on the craft and achieve professional-level results with every project.